What is hipot testing ?

A withstand voltage testing or hipot testing(high potential testing) is an essential electrical testing for electrical equipment to determine the effective of insulation. A hipot test is divided two parts AC hipot testing and DC hipot testing .

Proceeding with the hipot test is helpful to find the possible defects and Inadequate creepage and clearance distances during the manufacturing process.

What is AC Hipot Testing ?

AC hipot testing, also known as AC dielectric withstand testing, is a electrical safety test conducted on various electrical equipment and devices by applying on a AC voltage level . The purpose of this test is to verify the dielectric strength and insulation integrity of the equipment under test.

AC hipot testing is included power frequency , variable frequency and 0.1Hz very low frequency (VLF) test.

What is DC Hipot Testing ?

DC hipot testing is another type of electrical safety test performed on electrical equipment and devices, such as similar to AC hipot testing, but using a high DC voltage instead of AC.

DC Hipot Tester is applied to measure output voltage and leakage current for zinc oxide arresters,magnetic blowing arresters, power cables, generators,transformers,circuit breakers and other equipments, The precision meter can indicate output voltage and leakage current on digital meters .

Is VLF testing AC or DC ?

VLF Testing is a AC hipot tester that perform the withstand and diagnostic testing for test object at very low frequency 0.1 Hz to 0.01 Hz . It is applied for HV/MV cable, motor and generator and other high capacitive loads.

What is the difference between VLF and hipot?

As for the difference between vlf test and hipot testing, we have list out the performance on insulation damage, operation safety and Volume .

Here is a comparison for DC, Power Frequency, Variable Frequency, and 0.1Hz test.

| Aspects | DC Hipot Test | Power Frequency Hipot Test | Variable Frequency Hipot Test | 0.1Hz VLF Test |

| Insulation Damage | strong | slight | slight | slight |

| Operation Safety | relatively low | relatively low | relatively low | high |

| Wiring Difficulty | complicated | complicated | most complicated | simple |

| Volume | smallest | largest | large | small |

The advantage of vlf testing

In summary, VLF testing is better than the traditional dc hipot testing and power frequency testing, variable frequency testing .

1.More Effective at Detecting Insulation Weaknesses

One of the main advantages of VLF testing is its effectiveness at detecting insulation weaknesses. VLF testing is capable of detecting the ability of t withstand voltage breakdowns in cables, which are indicators of potential insulation failures. This makes VLF testing more effective than other testing methods

2. VLF testing safer

VLF testing is safer than other testing methods, such as DC testing. VLF tests use frequencies between 0.1 Hz and 0.01 Hz, allowing for testing at lower voltages while still achieving effective insulation testing. In contrast, hipot testing involves applying high voltages, often several times the rated voltage of the equipment under test.

VLF Hipot Testing can effectively reduced the risk of electrical shock. VLF testing equipment is designed with safety features such as interlocks and grounding devices to prevent accidents.

3.Less damaging

VLF testing typically applied lower level and low frequency can reduced the dielectric heating to extend the electrical materials’ service life. Besides VLF testing applies a sinusoidal waveform to the insulation system, mimicking the frequency and waveform of the power system. This gradual application of voltage reduces the likelihood of causing insulation breakdown or damage compared to the sudden voltage spikes associated with hipot testing.

Reduced Dielectric Heating: The lower frequencies used in VLF testing result in reduced dielectric heating within the insulation material. Dielectric heating occurs when an insulating material is subjected to an electric field, causing it to heat up. Higher frequencies, as used in hipot testing, can induce more dielectric heating, potentially leading to thermal stress and degradation of the insulation material. Lower frequencies, characteristic of VLF testing, mitigate this heating effect and thus reduce stress on the insulation.

4.Longer Cable Testing Capabilities

VLF testing can be used for cable testing over longer distances, making it ideal for testing underground cables or cables in hard-to-reach areas. This is because the VLF testing equipment generates high voltage at a frequency that allows it to penetrate the cable insulation and reach the conductor, regardless of the length of the cable.

5. Easier to Operate

VLF testers are portable and lightweight for technicians to transport on the scene testing . The portable test equipment enable electrical engineers to easy wire connecting and operation. The testing procedure is simple and can be performed by personnel with minimal training. This reduces the need for highly skilled personnel and can result in cost and time savings for the user

What is vlf testing in cables used to ?

VLF cable testing is a valuable diagnostic tool for assessing insulation integrity, detecting defects, localizing faults, and ensuring the reliability and safety of HV and MV cable systems in various industries such as power generation, transmission, distribution, and industrial applications.

Can VLF Testing Extend Cable Lifespan?

VLF testing is effective in detecting insulation defects such as voids, moisture ingress, delamination, and other anomalies within the cable insulation. By subjecting the cable to a high-voltage stress at a low frequency, VLF testing can reveal potential weaknesses that might lead to insulation breakdown or failure.

VLF testing acts like a health check-up for cables. By detecting potential issues early, it allows for timely repairs or maintenance. This proactive approach helps prevent major problems down the line, ensuring the cables remain reliable and operational for an extended period. Following VLF testing guidelines also ensures that cables meet safety standards, further contributing to their longevity. In essence, VLF testing plays a vital role in maintaining the health and lifespan of cables.

How do you do VLF cable test set for HV/MV cable?

VLF cable test set can be carried out the withstand voltage test for cable as per the bleow steps.

1. Firstly, unconnect VLF hipot tester to the test cable .

2. Use a 10kV megohmmeter to test the insulation resistance of each phase of test cable, and record the test value.

- Peak test voltage: Umax=3Uo, Uo is the rated working voltage between the cable conductor and the ground or the metal shield. For example: the rated voltage is 10KV cable, the single-phase rated voltage Uo: Uo=10/√3kV, so the test voltage peak value is: Umax=3Uo=3×10/√3kV=√3×10kV=17.32kV 4. Test time: 3 minutes.

4. It can be tested by phase separation. When the capacitance value of the test cable is within the load capacity of the test equipment, the three-phase cores of the test cable can be connected in parallel, and then the withstand voltage test can be carried out at the same time.

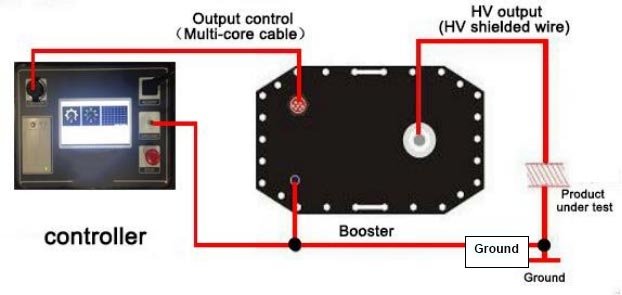

5. After connecting VLF high voltage booster and the test cable according to the method shown in the figure above. You can turn on the power supply and set the test frequency, time and voltage, as well as the overcurrent protection value and overvoltage protection value of the high voltage side, and then start the increasing voltage test. During the boosting process, the high-voltage circuit should be payed close attention to veryify whether there is abonomal noise. When the test voltage is raised, the test time is recorded and the test voltage value is read.

6. After the test time ended, the instrument will automatically stop. If there is no destructive discharge occurs during the test, it is considered to pass the withstand voltage test.

7. During the increasing voltage of withstand voltage test, if the current increases abnormally, the voltage is unstable, the test cable has peculiar smell, smoke or abnormal sound or flashing, etc., the boosting should be stopped immediately, and the reason should be inspected after the shutdown. If these phenomena are caused by the weak insulation of the test cable, the withstand voltage test is considered to be unqualified. If it is determined that the test cable is caused by air humidity or surface contamination, etc., the test cable should be cleaned and dried before testing.

8. During the test, if the insulation defect of the non-tested cable causes the overcurrent protection of the instrument, after the cause is identified, the full-time connection withstand voltage test should be performed again. Only “make-up time” trials shall not be performed