VLF testing is a withstand voltage testing mainly used on low voltage and middle voltage cable by the frequency range of 0.1 Hz to 0.01 Hz . It is to identify the potential failure in the insulation lay of cable by the instantaneous voltage.

Here we mainly talk about the common test the cable methods.

When it comes to testing cables, there are several common methods that are widely used in the industry. Two of the most commonly used testing methods for power cables are DC hipot testing and VLF cable testing.

DC hipot testing

The principle of DC hipot testing cable : Applying the DC voltage on the cable , the current flow through the cable conductor and cable insulation . The positive current flow from the test equipment to the cable, through the conductor and insulation, and then back from the negative end of the cable to the test device. The leakage current through insulation manterial can be measured during the dc hipot testing. The leakage current is caused by the passage of current through small defects or contaminants in the insulation material.

VLF testing

Principle : VLF testing adopts generate AC voltage with the accuracy very low frequency signal and high output power . The output voltage of a VLF generator is passed through an insulation load connected to the cable to be tested. The insulation load is a highly capacitive load which simulates the properties of the cable insulation material. Measure the current and voltage of cable conduct and insulation material and analyze the abnormal voltage and current waveform to check the cable insulation and potential faults.

DC hipot Testing VS VLF testing

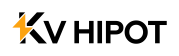

Many report and study on cable failures in developed utilities revealed the fact that this traditional method of DC hipot testing for cable such as XLPE (Cross-Linked Polyethylene) and EPR (Ethylene Propylene Rubber).

Due to the migration of charging carries in a dielectric under sustained dc voltage, resulting in electric field distortion, which can cause localized overheating of the cable and accelerated aging of the dielectric. There is also a risk of reduced the remaining service life of the cables with degraded polymeter insulation during DC testing .

Polymer-based insulation materials, particularly XLPE, have different electrical characteristics compared to traditional paper or oil-based insulation. DC voltage can form the space charges within the polymer material, leading to electrical stress concentrations and potential insulation breakdown. Additionally, the presence of moisture or impurities within the polymer insulation can further exacerbate the effects of DC voltage.

VLF testing has gained popularity for testing modern cables with polymer insulation. VLF testing applies an AC voltage at frequencies typically ranging from 0.01 Hz to 0.1 Hz. This low-frequency AC voltage helps to minimize the effects of space charges and reduces the risk of insulation breakdown.

Mostly industry standards does not regard dc hipot testing of cables XLPE and ERP as a cable maintenance testing . VLF testing is considered more suitable for assessing the withstand capability and insulation quality of modern cables with polymer-based insulation. It provides a more realistic and less damaging test method compared to DC testing. The VLF testing method allows for a more accurate evaluation of the cable’s condition and remaining life expectancy.

The advantage of VLF testing

Compared with the hipot testing and VLF cable testing , there are the below advantage key factors and analysis.

Lower Voltage Levels

VLF testing is proceed at lower voltage levels compared to hipot testing. Even if VLF testing still applies a relatively high voltage, it is lower than the voltage levels used in hipot testing. This lower voltage reduces the stress on the insulation material and decreases the possibility of causing damage.

In addition , VLF testing applies the voltage in a gradual way, compared to the abrupt voltage application in hipot testing. This gradual increase in voltage allows the insulation material to respond and adapt the applied stress more smoothly . That can reduce the risk of damage.

Reduced Dielectric Heating

The lower frequencies used in VLF testing can reduce the dielectric heating inner the insulation material. The dielectric material occurs the dielectric heating , leading it to heat up when the insulating material in an electric field. Higher frequencies such as hipot testing, can induce more dielectric heating, potentially leading to thermal stress and degradation of the dielectric material. VLF testing with lower frequencies can reduce the heating effect and the stress on the insulation .

Lower Electric Field Strength

The electric field strength inner the insulation material is directly proportional to the applied voltage. Lower voltage levels applied in VLF testing result in lower electric field strengths within the insulation compared to hipot testing applied with the high voltage. This reduced electric field strength diminishes the possibility of electrical breakdown and insulation damage.

Sinusoidal Waveform

VLF testing applies a sinusoidal waveform to the insulation system, mimicking the frequency and waveform of the power system. This gradual application of voltage reduces the likelihood of causing insulation breakdown or damage compared to the sudden voltage spikes associated with hipot testing.

Requirements for Cable Testing and International Standards

IEC 60060-3 High-voltage test techniques – Part 3: defines the requirements for HV field testing on-site. IEEE Std 400.2 — IEEE guide for field testing and evaluation of the Insulation of power cable systems using Very Low Frequency (VLF)

IEC 60060-3: This standard is part of the IEC 60060 series, which provides guidelines for high-voltage test techniques. Specifically, Part 3 of this standard, titled “Definitions and requirements for on-site testing,” addresses various aspects of on-site testing, including VLF testing. It defines the terminology, test procedures, and requirements for conducting VLF tests.

IEEE Std 400.2: This standard is published by the Institute of Electrical and Electronics Engineers (IEEE). It provides the guidance for field testing and evaluating the insulation of shielded power cable systems using VLF testing methods. This standard covers topics such as test equipment, VLF testing procedures, interpretation of test results, and safety considerations.

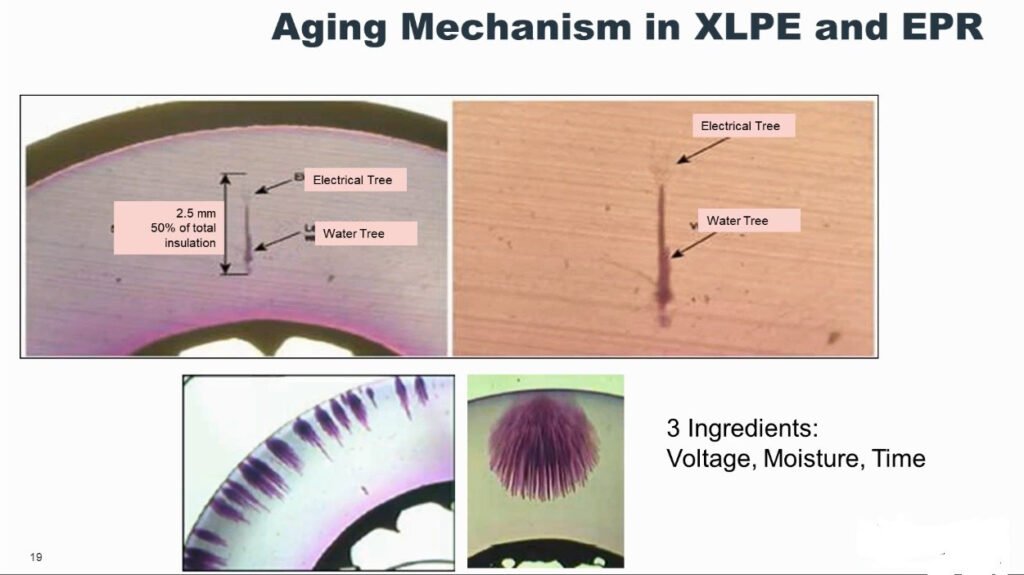

IEEE 400.2 VLF standard about the VLF testing methods and VLF testing procedures.

It uses the frequency range 0.01Hz to 0.1Hz . The frequency selection is depend on the the load of power cable .The test time of VLF cable testing vary from 15 mins to 60 mins . IEEE 400.2 standard also provide the suggestion about the test voltage . The test voltage can be calculated as a multiple of the cable’s nominal phase-to-phase voltage. Test voltage range is from 1.5 U0 to 3 U0 (U0 represents the cable’s nominal phase-to-phase voltage) . Please refer to the data table which is taken from the IEEE 400.2-2013 standard.

IEEE 400.2 Field Test Voltages

What do you consider when purchasing a VLF cable tester ?

When purchasing a Very Low Frequency (VLF) tester, you need to consider several key factors to ensure the equipment meets your specific testing needs and that you achieve reliable and accurate results. Here are some of the main considerations:

- Frequency Range

It is essential to verify that the VLF tester covers the appropriate frequency range for the types of cables you will test. The frequency range typically vary from 0.1 Hz and 0.01 Hz. The specific requirements should be decided the specific cable .

- Test Voltage Level

Ensure that VLF tester can generate the necessary voltages to effectively test your cables. The voltage level should be suitable for the maximum voltage of the cables you will be testing.

- Cable Length and Capacitance

Consider the maximum cable length and capacitance that the VLF tester can applied in . Ensure that it is useful for the cables you will be testing to avoid limitations or inaccuracies in the testing process.

- Portability and Ease of Use:

Evaluate the portability and user-friendliness of the VLF tester. If you need to perform the cable tests in various on-site. The size , weight and mobility of the equipment should be considerable. Besides, An visual interface and easy-to-use features can enhance efficiency and reduce the potential errors.

- Safety protection of the equipment

VLF tester should includes essential safety protection features to protect the operator and the equipment. The protection function has the feature of rising voltage protection , down voltage protection and grounding systems.

- Compliance with Standards:

Verify that the VLF tester complies with relevant industry standards and regulations. This ensures that the testing procedures and results are in line with accepted practices and can be relied upon.

- Data Storage function:

It is helpful that VLF tester has the feature of data storage function .You can will check the data result after testing. These features can facilitate data management, analysis, and reporting.

- Warranty and Technical Support:

The warranty and technical support are important. A reliable warranty ensures that you are protected against any defects or malfunctions in the equipment during a specified period. No-worry warranty and professional technical support can provide peace of mind and assistance in case of any issues or concerns.

- VLF Tester Price :

The cost of VLF testers can vary depending on factors such as the brand, model, features, and specifications. Different brand has different price . VLF testers are specialized equipment .You need to evaluate the VLF tester cost according to your budget and the product performance.

KV Hipot Power Equipment Helps You Diagnosis Your Power Cable with Professional VLF Cable Testing Equipment.

We offers a comprehensive range of VLF series ultra-low frequency high voltage generators that incorporate state-of-the-art digital frequency conversion technology. These generators feature microcomputer control, enabling fully automated operation for boosting, bucking, measurement, and protection. Additionally, manual intervention is possible during the automatic boosting process.

Adopting the electronic design, these generators are compact and lightweight. They come equipped with a large-screen LCD display that provides clear and intuitive information, including output waveforms. The generators also offer the convenience of a built-in printer for generating test reports.

We can effectively help you to test the power cable to make your cable maintenance test job easier . Accurately diagnosis the cable can reduce operational costs.

FAQ

1) How long cable can I test by VLF cable tester?

The test cable length is depended on the type of VLF tester . You need to consider the cable voltage level and frequency .

For example : VLF-30 is the one of most popular VLF tester. It can output 30kV peak voltage . At 0.1Hz, you can test 1.5km, 0.3uF cable. At 0.01Hz, It can test 10km 15km,3uF cable.

2)What factors need to be considered to ensure the accurate and reliable for VLF testing ?

Choose the test voltage : It is crucial to choose a voltage level that is within the safe operating limits of the cable and can effectively detect any insulation weaknesses or faults. Test voltage range is from 1.5 U0 to 3 U0 (U0 represents the cable’s nominal phase-to-phase voltage). You can refer to the voltage according to IEEE 400.2 Field Test Voltages figure 2.

The right frequency: The selection of the frequency depends on factors such as the cable length, capacitance, and the specific testing requirements. Lower frequencies are often used for longer cables as they help overcome the cable’s capacitance and provide a more accurate representation of the cable’s insulation condition.

Test time:The duration of the VLF test is an important factor. The test duration should be sufficient to allow for the identification of any potential insulation weaknesses. According to the standard IEEE 400.2, the test time vary able from 15 mins to 60 mins. The recommended time for withstand voltage testing is about 30 mins.

If your question is not addressed here or you need a more complete answer, please contact us info@kvhipot.com or chat us by whatspp +8618062060691 and we will be happy to assist you