A transformer bushing is an insulated conductor that safely carries high-voltage current through the grounded metal tank of a transformer. It provides both electrical conduction and insulation, preventing short circuits between the live conductor and the transformer body. In my work at the factory, I’ve seen how a single, seemingly small component like a bushing can be the weak link in a million-dollar asset. It’s not just a pass-through for a wire; it’s a highly engineered piece of equipment that has to handle immense electrical and mechanical stress.

A faulty transformer bushing can lead to a catastrophic failure. Ignoring this component risks explosions, costly downtime, and serious safety hazards for your team.

Understanding its types, function, and importance is the first step toward ensuring the long-term reliability of your power transformers. Let’s break down what makes these components so critical.

What are the main types of transformer bushings?

Choosing the wrong bushing type can lead to incorrect maintenance or replacement. This mistake can compromise safety and lead to premature failure of the new component. The main types of transformer bushings are defined by their materials and design. These include traditional porcelain, modern composite, oil-impregnated paper (OIP) for high-voltage applications, and advanced capacitive graded bushings for superior electrical field control. The materials and internal design of a bushing dictate its application and performance.

From our manufacturing perspective at KV HIPOT, we see customers moving towards composite and advanced capacitive bushings for new installations due to their superior performance in polluted environments and at higher voltages. However, the vast majority of transformers in service still rely on porcelain and OIP types, making it essential for technicians to understand how to test and maintain all varieties. Each type has a specific purpose, and knowing the difference is crucial for any engineer or maintenance professional working with high-voltage equipment.

| Bushing Type | Key Material / Design | Primary Advantage | Common Application |

|---|---|---|---|

| Porcelain | High-strength ceramic insulator. | Durable, cost-effective, long service history. | Traditional choice for all voltage levels. |

| Composite | Silicone rubber or epoxy resin over a fiberglass core. | Lightweight, excellent pollution resistance. | High-pollution areas, seismic zones. |

| Oil-Impregnated Paper (OIP) | Kraft paper insulation impregnated with mineral oil. | Excellent dielectric properties for high voltage. | Main bushings on large power transformers. |

| Capacitive Graded | Conductive layers (foils) embedded in insulation. | Uniformly distributes electric field stress. | Extra-High Voltage (EHV) & UHV transformers. |

What is the function of a transformer bushing?

Thinking a bushing is just a simple insulator is a dangerous oversimplification. This mindset causes technicians to overlook its critical dual role in conducting massive currents safely. The main function of a transformer bushing is twofold. It must safely conduct high electrical current from the outside line into the transformer windings.

At the same time, it must insulate that live conductor from the grounded metal tank. These two functions, conduction and insulation, are equally important. The central conductor must handle the full load current without overheating. At the same time, the insulating body must withstand the full system voltage, preventing a flashover to the metal tank. In high-voltage bushings, this is achieved with a sophisticated design using “condenser layers.”

These are conductive foils inserted within the paper insulation. They help distribute the electrical field evenly across the insulator, reducing stress at any single point. Without this careful voltage grading, the electrical stress near the grounded tank flange would be immense, leading to a quick breakdown of the insulation. So, a bushing is not just an insulator; it’s an active electrical field management device.

| Function | Description | Why It’s Critical |

|---|---|---|

| Conduction | Provides a continuous, low-resistance path for electrical current to flow into or out of the transformer. | Prevents overheating and energy loss. A poor connection can lead to a thermal runaway and failure. |

| Insulation | Creates a robust, high-dielectric barrier between the high-voltage conductor and the grounded tank. | Prevents phase-to-ground faults, which are catastrophic events that destroy the transformer. |

| Voltage Grading | Distributes the electrical field evenly along the length of the bushing, both internally and externally. | Reduces electrical stress concentrations, preventing insulation breakdown and external flashovers. |

What is the significance of a transformer bushing?

A bushing often looks like a passive and robust part of a transformer. However, it is one of the components most likely to fail, often with explosive and devastating results. The significance of a transformer bushing lies in its role as a major stress point. It must endure constant electrical, thermal, and mechanical stress, making it a primary indicator of transformer health and a common point of catastrophic failure.

A bushing is where the internal, protected environment of the transformer meets the external, uncontrolled environment. It’s exposed to weather, pollution, and vibration. Internally, it handles the full electrical load and voltage stress. This combination makes it uniquely vulnerable. Industry data consistently shows that bushing failures are a leading cause of transformer explosions and fires.

For example, a CIGRE working group report (A2.37) highlighted bushings as a key contributor to transformer failures. Because of this high risk, testing bushings is a critical part of any maintenance program. Tests like Power Factor/Tan Delta can provide early warnings of degradation, allowing for replacement before a disaster occurs. Its health is directly tied to the transformer’s survival.

| Failure Mode | Potential Cause | Consequence |

|---|---|---|

| Insulation Breakdown | Moisture ingress, aging of paper, internal partial discharge. | Internal short circuit, catastrophic bushing failure, transformer fire/explosion. |

| External Flashover | Pollution, moisture on the insulator surface (porcelain/polymer). | External arc, power outage, potential damage to the insulator surface. |

| Overheating Connection | Loose or corroded internal or external connections. | Thermal runaway, melting of components, potential for internal faults. |

| Oil Leak (OIP Type) | Gasket failure, cracks in the porcelain. | Loss of insulation and cooling, moisture ingress, leading to internal failure. |

What electrical testing is required for a transformer bushing?

A hidden flaw in a transformer bushing can go undetected for years. But when it fails, it can cause an explosion, leading to costly outages and a serious safety crisis.

Key electrical tests for a transformer bushing include Tan Delta, Insulation Resistance, AC Withstand Voltage, and Partial Discharge testing. These diagnostic and proof tests are essential for detecting insulation degradation, contamination, and manufacturing defects before they lead to a catastrophic failure.

From my experience at KV HIPOT, I can tell you that a transformer is only as strong as its weakest component, and bushings are often that weak link. They face immense electrical and environmental stress. Relying on visual inspection alone is not enough. You need a comprehensive testing strategy to understand what’s happening inside the insulation.

Let’s break down the most critical electrical tests that give you a clear picture of a bushing’s health, ensuring the safety and reliability of your power assets.

How does Tan Delta testing assess bushing health?

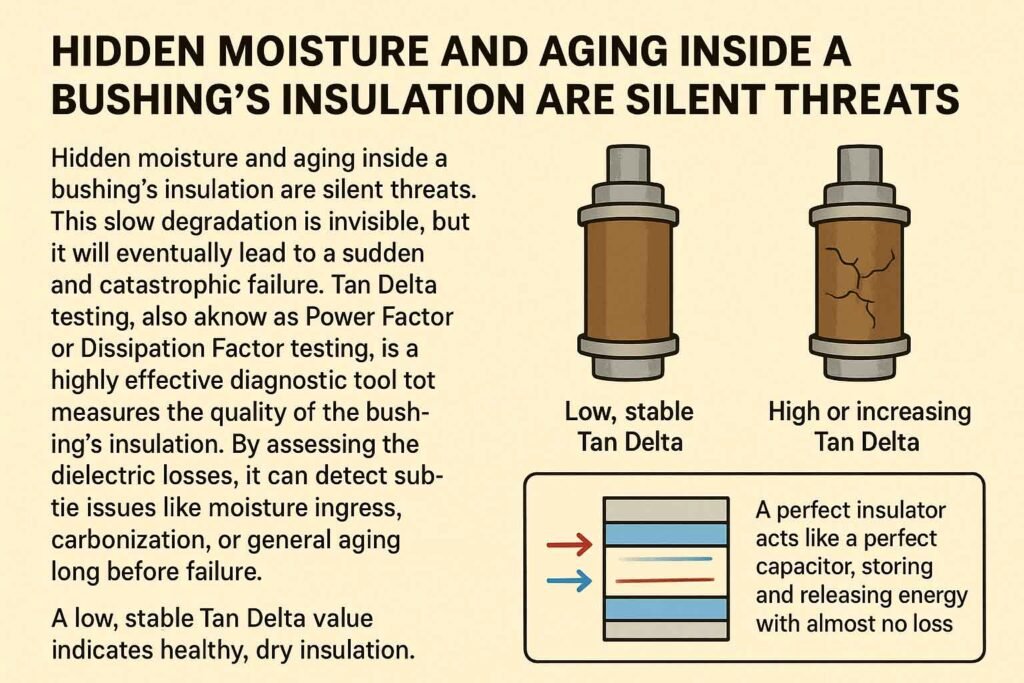

Hidden moisture and aging inside a bushing’s insulation are silent threats. This slow degradation is invisible, but it will eventually lead to a sudden and catastrophic failure. Tan Delta testing, also known as Power Factor or Dissipation Factor testing, is a highly effective diagnostic tool that measures the quality of the bushing’s insulation. By assessing the dielectric losses, it can detect subtle issues like moisture ingress, carbonization, or general aging long before the bushing fails.

A low, stable Tan Delta value indicates healthy, dry insulation. In contrast, a high or increasing value is a clear warning sign that the insulation is compromised and needs attention. This test gives you an essential early warning. The principle behind Tan Delta is straightforward. A perfect insulator acts like a perfect capacitor, storing and releasing energy with almost no loss.

However, when insulation degrades or gets wet, it starts to conduct a small amount of current, losing energy as heat. The Tan Delta test measures this energy loss. We use specialized test sets, like the ones we manufacture, to apply an AC voltage and precisely measure the capacitive and resistive currents. The ratio between these gives the Tan Delta value. It is the most reliable method for trending the condition of a bushing’s insulation over its service life. Regular testing allows you to spot a negative trend and schedule a replacement before a major failure occurs.

| Test Result | Indication | Recommended Action |

|---|---|---|

| Low & Stable | Healthy, dry, and clean insulation. | Continue with routine periodic testing (e.g., every 3-5 years). |

| Slightly Elevated | Possible minor contamination or aging. | Increase testing frequency. Investigate potential causes. |

| High / Increasing | Significant moisture, contamination, or aging. | Urgent investigation required. Prepare for bushing replacement. |

| Very High | Severe degradation. Imminent failure risk. | Immediately remove the transformer from service for replacement. |

Why is Insulation Resistance testing important for bushings?

Surface contamination from dust, salt, or industrial pollution can create a conductive path. This path can easily lead to a dangerous electrical flashover during wet or humid conditions. Insulation Resistance (IR) testing is a fundamental test that verifies the integrity of the insulation against surface contamination and major moisture ingress.

Using a high DC voltage from a megohmmeter, the test measures the total resistance between the central conductor and the grounded mounting flange. A high resistance reading, typically in the giga-ohm (GΩ) range, confirms that the insulation is clean and sound. A low reading is a strong indicator of a problem that could compromise the bushing’s ability to insulate properly, flagging it for cleaning or further investigation.

While Tan Delta testing diagnoses the quality of the bulk insulation material, the IR test is an excellent spot-check for the overall insulation system, especially the external surfaces. It’s a quick, simple, and effective way to identify problems like cracked porcelain, failing gaskets, or severe surface pollution.

For a more thorough assessment, we often recommend performing a Polarization Index (PI) test, which is a 10-minute to 1-minute ratio of insulation resistance readings. A low PI value (less than 2) often points directly to moisture contamination within the insulation structure. It’s a foundational test that should be part of any maintenance routine.

| Insulation Resistance Value (at 20°C) | Condition Assessment | Recommended Action |

|---|---|---|

| > 10 GΩ | Excellent condition. Insulation is clean and dry. | Record value and continue routine maintenance. |

| 1 GΩ – 10 GΩ | Good condition. Acceptable for service. | Record value and monitor for any downward trend. |

| 100 MΩ – 1 GΩ | Questionable. May indicate surface contamination. | Clean the bushing insulators and re-test. |

| < 100 MΩ | Poor condition. Indicates severe moisture or damage. | Do not energize. Investigate immediately. |

What does an AC withstand voltage test prove for a bushing?

After manufacturing or a significant repair, you cannot be sure if a bushing is truly safe. Putting a potentially flawed component into service is a massive risk that could lead to immediate failure. An AC withstand voltage test, commonly known as a hipot test, is a “go/no-go” test that proves the fundamental insulation strength of a bushing.

It involves applying a high AC voltage—significantly higher than the normal operating voltage—for a fixed duration, typically one minute. The bushing passes the test if it withstands this electrical stress without any breakdown, flashover, or excessive leakage current. This test confirms that the bushing has no major defects in its material or construction and possesses the basic dielectric strength required for safe operation.

It is the final quality check. Unlike diagnostic tests that assess condition, the withstand test is designed to find weak spots by stressing the insulation. Because of its high-stress nature, it is primarily performed in the factory after manufacturing (Factory Acceptance Test) or in a repair facility.

It is generally not recommended for routine field maintenance on aged equipment, as the high voltage could potentially damage already weakened insulation. The test voltage levels are specified by international standards like IEC 60137 or IEEE C57.19.00. Passing this test gives confidence that the bushing’s insulation system is sound and ready for service.

| Aspect | Description | Interpretation |

|---|---|---|

| Purpose | To verify the fundamental dielectric strength of the insulation. | Confirms there are no major manufacturing defects or damage from repairs. |

| Procedure | Apply a specified high AC voltage (e.g., 2x Rated Voltage + 1kV) for one minute. | A simple Pass/Fail result. |

| Pass | No breakdown, flashover, or sharp increase in leakage current occurs. | The bushing is considered safe and has the required insulation integrity. |

| Fail | A disruptive discharge (breakdown or flashover) occurs. | The bushing is defective and must not be put into service. |

How does partial discharge testing find hidden bushing defects?

Tiny voids or cracks buried deep inside the insulation are ticking time bombs. These small defects are invisible and slowly degrade the surrounding material until it fails without warning. Partial Discharge (PD) testing is the most sensitive diagnostic method for detecting these small, hidden defects inside a bushing’s insulation system.

A partial discharge is a small electrical spark that doesn’t completely bridge the insulation. It occurs in gas-filled voids, cracks, or at the interface of different insulating materials when the electrical stress is high enough. PD testing uses specialized equipment to “listen” for the high-frequency signals or ultrasonic noise generated by these tiny sparks.

Finding PD activity is a direct indication of an active degradation process that will eventually lead to complete failure. Think of PD as a cancer for insulation. Each tiny discharge slowly eats away at the insulating material, creating carbonized tracks and further weakening the structure. This process can continue for years until the remaining insulation can no longer withstand the operating voltage, leading to a sudden and complete breakdown.

The test can identify the voltage at which PD starts (Partial Discharge Inception Voltage, PDIV) and stops (Partial Discharge Extinction Voltage, PDEV). Ideally, the PDIV should be well above the maximum operating voltage of the bushing. This advanced test is critical for quality assurance in the factory and for condition assessment of critical high-voltage assets in the field.

| PD Measurement | Significance | Implication for Bushing Health |

|---|---|---|

| PD Inception Voltage (PDIV) | The voltage at which partial discharge activity begins. | A low PDIV (below operating voltage) indicates a serious defect. |

| PD Extinction Voltage (PDEV) | The voltage at which partial discharge activity stops as voltage is lowered. | A PDEV much lower than the PDIV can indicate a more severe issue. |

| PD Magnitude (pC) | The intensity of the discharge, measured in pico-Coulombs. | High PD magnitude or an increasing trend indicates accelerating degradation. |

| PD Location | Advanced techniques can sometimes locate the source of the PD. | Helps pinpoint the defect for analysis (e.g., internal void vs. surface issue). |

Testing transformer bushings is critical for ensuring the reliability and safety of power transformers. Bushings are high-voltage components that allow electrical conductors to pass safely through grounded transformer tanks. Over time, they can degrade due to moisture ingress, insulation breakdown, or partial discharge activity. The following are the key electrical tests typically performed on transformer bushings:

Conclusion

Routine electrical testing of transformer bushings is essential for early detection of insulation problems and preventing catastrophic failures. The most commonly used tests are capacitance and tan delta, insulation resistance, and power factor. Advanced diagnostics like DFR and PD testing provide deeper insights and are increasingly used in condition-based maintenance programs.