You get a high Tan Delta reading from your transformer oil, and your heart sinks. This could mean insulation failure is near, forcing a costly decision. Is the result accurate, or is it a testing error? The top five technical hurdles to accurate Tan Delta measurement are trace moisture, ionic contaminants, temperature instability, electrostatic interference, and the combined effect of these factors.

Overcoming them requires precise sample handling, meticulous equipment calibration, and a deep understanding of oil chemistry. Getting a reliable reading isn’t just about pushing a button; it’s about controlling every variable that can corrupt the result. Each hurdle presents a unique challenge that can turn a routine test into a diagnostic nightmare. Let’s break down each of these technical hurdles to understand why they occur and how you can overcome them to get data you can trust.

What are the factors affecting the Tan Delta of transformer oil?

You need to diagnose a failing transformer. The Tan Delta test is your first step, but the result is ambiguous, leaving you unsure of what to test next. The primary factors affecting the Tan Delta of transformer oil are moisture content, conductive particles, oil degradation byproducts (like acids), and temperature. Each of these increases the dielectric loss of the oil, leading to a higher Tan Delta value and indicating reduced insulating capability.

In my experience, the biggest technical challenge is understanding that these factors work together. Engineers often try to isolate the cause of a high reading to a single source. But in reality, moisture is far more damaging in oil that also has conductive particles from insulation aging. The particles create pathways for leakage current that are made worse by water molecules. This is why a high Tan Delta reading should always trigger follow-up tests for particle count and acidity. This gives you a complete picture of the contamination, rather than just a single data point. Understanding this synergistic effect is key to accurate diagnosis.

| Factor | How it Affects Tan Delta | Typical Source |

|---|---|---|

| Moisture Content | Increases the polarity of the oil, causing more energy loss as heat. | Atmospheric humidity, paper insulation degradation. |

| Ionic Contaminants | Creates free-moving charge carriers, increasing conductive leakage current. | Oil oxidation, byproducts from cellulose decay. |

| Conductive Particles | Forms microscopic bridges for current to leak through the oil. | Mechanical wear, insulation aging, sludge. |

| Temperature | Lowers oil viscosity, allowing all contaminants to move more freely. | Ambient conditions, operational load of the transformer. |

How does trace moisture content disproportionately affect Tan Delta results?

Your oil sample looks perfectly clean and dry, yet the Tan Delta reading is alarmingly high. You suspect contamination, but you can’t see it because the culprit is invisible. Even trace moisture, measured in parts per million (ppm), dramatically increases the Tan Delta reading. Water molecules are highly polar and align with the electric field, dissipating energy as heat. This effect is magnified at higher temperatures, making moisture a primary cause of failing results. Water is the number one enemy of transformer insulation.

When we talk about moisture, we are usually referring to dissolved water within the oil, not free water settled at the bottom. These microscopic, dissolved water molecules are what cause the problem during a Tan Delta test. Because they are polar, they try to physically rotate to align with the alternating AC electric field. This constant movement generates friction and heat, which is measured as dielectric loss. According to standards like IEEE C57.106, even a few ppm of moisture can be the difference between a pass and a fail, especially in service-aged oil. This is why meticulous sample handling, using clean and dry syringes and bottles, is non-negotiable for an accurate test.

| Moisture Level (ppm) | Impact on Tan Delta (Typical) | Condition of Oil |

|---|---|---|

| < 10 ppm | Very Low / Excellent | New, well-processed oil |

| 10 – 20 ppm | Moderate Increase / Acceptable | Service-aged oil in good condition |

| 20 – 30 ppm | Significant Increase / Marginal | Requires investigation or dehydration |

| > 30 ppm | High / Unacceptable | Oil is wet, immediate action needed |

How can ionic contaminants from oil degradation skew test readings?

The oil in your aging transformer passes the moisture test, but the Tan Delta is still out of spec. What other invisible contaminants are ruining your insulation and giving you bad readings? Ionic contaminants, primarily acidic compounds formed from oil oxidation, significantly increase oil conductivity. These free ions move under the influence of the electric field, creating a leakage current that directly increases the dielectric loss and pushes Tan Delta readings higher. Transformers generate heat. Over years of service, this heat, combined with oxygen and the catalytic effect of copper windings, causes the insulating oil to oxidize.

This chemical breakdown creates byproducts, including organic acids and sludge. These acids are ionic, meaning they exist as charged particles within the oil. Unlike polar water molecules that just rotate, these ions physically move through the oil when voltage is applied, creating a small but significant conductive current. This is a direct leakage path through the insulation. This problem is often worse in older transformers with aged paper insulation, which also releases acidic compounds as it degrades. This is another example of the synergistic effect: degraded oil not only has its own contaminants but also becomes more hygroscopic, meaning it absorbs atmospheric moisture more readily, making a bad situation worse.

| Contaminant Type | Chemical Origin | Effect on Measurement |

|---|---|---|

| Carboxylic Acids | Oxidation of hydrocarbon oil at high temperatures. | Increases the number of mobile charge carriers (ions). |

| Sludge Precursors | Early-stage, soluble oxidation byproducts. | Increases both polarity and conductivity. |

| Metallic Soaps | Reaction of acids with copper or iron from windings/core. | Highly conductive ions that significantly raise losses. |

| Cellulose Decay Products | Furans and acids from degrading paper insulation. | Introduce both moisture and ionic contaminants. |

Why is maintaining a stable test temperature (90°C) so critical?

You run the exact same oil sample twice and get two completely different Tan Delta readings. Your equipment seems fine, but the results are inconsistent and impossible to trust for trending. Maintaining a stable test temperature, typically 90°C per ASTM D924, is critical because oil viscosity and contaminant mobility change dramatically with temperature. An unstable temperature causes inconsistent readings, making it impossible to trend data or accurately compare results against standards. The physics are simple: as oil gets hotter, its viscosity drops. It becomes thinner and flows more easily. This allows any contaminants—water molecules, ions, particles—to move much more freely when the test voltage is applied.

More movement equals more energy loss, which means a higher Tan Delta reading. This is why international standards like ASTM D924 and IEC 60247 specify exact test temperatures, most commonly 25°C and 90°C. Testing at 90°C is particularly useful because it simulates the transformer’s operating temperature and makes subtle contamination issues much more obvious. If your test cell temperature fluctuates by even a few degrees during the measurement, the viscosity will change, and your result will be unreliable.

| Temperature Variation | Effect on Oil Viscosity | Impact on Tan Delta Reading |

|---|---|---|

| Too Low (e.g., 85°C) | Viscosity is higher than standard. | Contaminant movement is restricted, giving a falsely low/good reading. |

| Correct (90°C ± 1°C) | Viscosity is at the standard reference point. | The reading is accurate and comparable to historical data and limits. |

| Too High (e.g., 95°C) | Viscosity is lower than standard. | Contaminant movement is exaggerated, giving a falsely high/bad reading. |

| Unstable Temperature | Viscosity is constantly changing. | The reading is inconsistent and non-repeatable. |

How can you mitigate the effects of electrostatic interference during measurement?

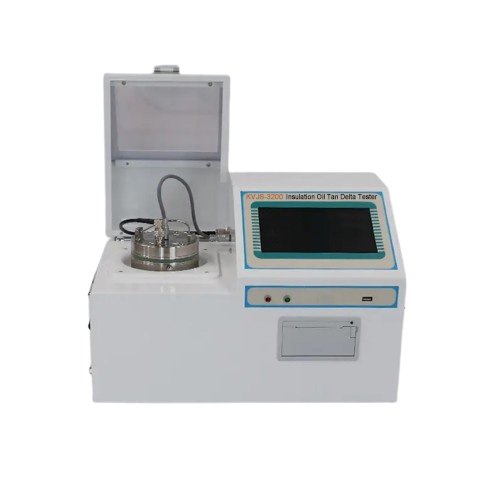

You are performing a sensitive Tan Delta test in a high-voltage substation. The air is buzzing with electrical noise, and you are worried it’s corrupting your extremely low-current measurements. To mitigate electrostatic interference, use a properly shielded test cell and ensure all equipment is grounded to a single, common point. Modern Tan Delta testers use advanced digital filtering and guarded electrode technology to isolate the measurement signal from external noise.

A Tan Delta test is a measurement of inefficiency. It works by detecting the tiny leakage current that flows through the oil. We are talking about currents in the nanoampere or even picoampere range. In an electrically noisy environment like a substation, stray electric fields from energized equipment can easily induce a current in your test leads that is much larger than the signal you are trying to measure.

This external noise will completely overwhelm the real measurement. The solution is threefold. First, the test cell and leads must be shielded to block external fields, similar to how a coaxial cable works. Second, a “guard” electrode is used in the test cell. This guard intercepts any stray currents and shunts them safely to ground, away from the sensitive measurement circuit. Third, a single-point grounding strategy prevents ground loops, which are another source of noise.

| Mitigation Technique | Principle of Operation | Practical Implementation |

|---|---|---|

| Shielding | Blocks external electric fields from reaching the measurement leads. | Using a three-part, enclosed test cell and shielded coaxial cables. |

| Guarding | Intercepts internal stray currents and bypasses the measurement circuit. | A third electrode in the test cell connected to a special guard terminal. |

| Digital Filtering | Software algorithms analyze the signal and remove noise at specific frequencies. | Built-in feature of modern, microprocessor-controlled test sets. |

| Single-Point Grounding | Prevents small voltage differences between ground points from creating noise loops. | Connecting all test equipment grounds to the same physical earth point. |