How do you regenerate lead acid batteries?

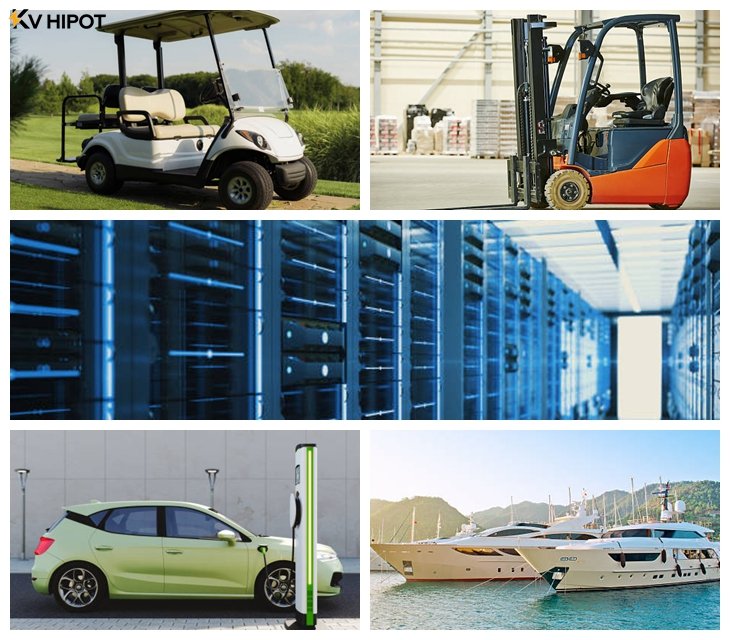

Lead acid batteries are widely applied in various field. The common application is used on electric vehicle ,trucks, golf cars , forklifts , telecom , UPS system and critical emergency DC power system. Lead acid batteries occurs the sulfation during the discharge and inadequate charge , resulting in the formation of an insulation layer on the battery plates.

When there is too much sulfation in a battery , it may lead to the following issues

- Reduced capacity: Sulfation leads to a decrease in the battery’s capacity. The formation of lead sulfate (PbS) layer reduces the effective reaction surface area of the electrode plates, thereby lowering the battery’s energy storage capability.

- Increased internal resistance: The presence of sulfation layer increases the internal resistance of the battery. This results in reduced energy conversion efficiency during charging and discharging processes, and may cause the battery to generate heat.

- Decreased battery performance: Sulfation leads to deteriorated discharge characteristics of lead-acid batteries, such as voltage drop and reduced power output. This means that the battery’s performance and reliability in supplying power are affected.

- Shortened lifespan: Sulfation accelerates the aging process of lead-acid batteries, leading to a shortened lifespan. The presence of the sulfation layer promotes further corrosion and damage.

- Risks: In extreme cases, sulfation can lead to the generation of hydrogen gas inside the lead-acid battery, increasing the risk of battery leakage, gas accumulation, and even explosion.

When batteries are vulcanized seriousely . Your batteries will hard to charge and have a bad capacity . If your forklifts and golfcars are suffering these systoms . It is time to activate the batteries by the battery regneration process .

What is battery regeneration ?

Battery regeneration is a process of restoring or rejuvenating the performance and capacity of a rechargeable battery that has experienced degradation or reduced efficiency over time.This technique is primarily applied to lead-acid batteries commonly used in various applications such as automotive batteries, uninterruptible power supplies (UPS), and industrial equipment.

Lead-acid batteries can suffer from the sulfation affect their performance,which occurs when lead sulfate crystals accumulate on the battery plates and reduce its capacity.

Battery regeneration aims to reverse or mitigate these effects, thereby extending the battery’s useful life and improving its performance.

The regeneration process typically involves applying a specialized high-frequency electrical pulse or current to the battery, which helps break down and dissolve the accumulated lead sulfate crystals. This electrical pulse, combined with the battery’s normal charging and discharging cycles, helps restore the battery’s capacity and overall efficiency.

It’s important to note that battery regeneration may not completely restore a battery to its original condition, especially if it has suffered severe damage or if other internal components of the battery are faulty. However, it can significantly improve the battery’s performance, extend its lifespan, and reduce the need for premature battery replacement

Why do you need battery regeneration ?

There are below several benefits for Battery regeneration:

Extended Battery Life

Regenerating a battery can significantly extend its lifespan by reversing the effects of degradation, such as sulfation. This allows the battery to maintain its performance and capacity for a longer period, reducing the need for frequent replacements.

Cost Savings

By rejuvenating degraded batteries, battery regeneration helps reduce the costs associated with purchasing new batteries. This is especially beneficial in applications where batteries are expensive or need to be replaced frequently, such as in automotive, industrial, or renewable energy systems.

Improved Performance

Regenerating a battery can enhance its overall performance. By breaking down the sulfation layer or other detrimental deposits, the battery’s capacity, voltage output, and charge acceptance can be improved, resulting in better reliability and efficiency.

Environmental Sustainability

Battery regeneration promotes environmental sustainability by reducing the number of batteries that end up in landfills. Extending the life of batteries through regeneration helps conserve natural resources and minimizes the environmental impact associated with battery production and disposal.

Reduced Downtime

In applications where batteries are critical, such as backup power systems or electric vehicles, regeneration can minimize downtime. By restoring the battery’s performance, it ensures that the battery operates optimally, avoiding disruptions and costly downtime.

Enhanced Energy Efficiency

Regenerated batteries tend to have improved energy efficiency. By removing sulfation or other detrimental layers, the battery can deliver energy more efficiently, reducing energy waste and improving overall system efficiency.

Maintenance and Reliability

Battery regeneration can be part of a proactive maintenance strategy. By regularly regenerating batteries, potential issues can be identified and addressed, ensuring the reliability and longevity of the battery system.

How do you regenerate lead acid batteries by battery activator ?

Battery Preparation

Disconnect the battery from any connected devices or vehicles. Clean the battery terminals and ensure they are free from corrosion or dirt.

Battery Regenerator Setup

Choose the suitable battery regenerator according to the battery specification . Then set the parameter of charging and discharge battery voltage and battery capacity .

Regeneration Process

Start the regeneration process as per the regenerator’s instructions. It can set multiple cycles of charging and discharging to activate the lag batteries and restore battery performance.Typically, this involves applying a specific current or voltage pattern to the battery to break down sulfation.

Monitoring

During the regeneration process, If you need to monitor the battery’s voltage using the regenerator’s display or monitoring system. This helps ensure the battery is regenerating properly and prevents any overheating.

Charging

After regeneration, please connect the regenerator with the battery . Charge the battery fully to restore its capacity and ensure optimal performance.

Post-Regeneration Testing

Once the battery is fully charged, conduct a capacity test or use a battery analyzer to assess its performance. This will help determine if the regeneration process was successful in restoring the battery’s capacity.

Don’t Compromise on Quality – Shop for Premium Quality Battery Regeneration.

KV Hipot is an industry-leading manufacturer and supplier of battery testing solutions. We have been shipping exceptional quality products, including battery discharge equipment, battery regeneration on time.