A transformer is a vital part of the power industry since it transmits electrical energy efficiently across different voltage levels. Same with any electrical equipment, transformers are inevitable to breakdowns and faults over time. Hence , it is crucial to identify and diagnose these faults to maintain a reliable power supply preventing costly downtime, and ensure optimal performance. Transformer test bench products can effectively detect and maintain your transformer. In this article, we will explore the significant role transformer test bench products play in diagnosing faults in transformers, enabling efficient electrical troubleshooting and effective maintenance.

Common transformer faults and issues

Transformer Common Faults

Transformers can experience various faults throughout their lifespan, which can compromise their performance and reliability. Some common transformer faults are included the electrical faults in transformers, thermal faults and mechanical issues.

Here we discuss the main faults electrical faults and thermal faults.

Electrical Faults

An electrical fault is an abnormal condition in a power system or electrical equipment. Electrical faults in transformers can arise due to various reasons including insulation breakdown, short circuits, open circuits, and winding faults.

1)Transformer Insulation breakdown

When insulation system fails , there is insulation breakdowns occurs, leading to reduced dielectric strength and potential arcing on the electrical system . That can be caused by aging, contamination, excessive temperature, or mechanical stress. Symptoms of insulation breakdown include abnormal heating, voltage fluctuations, and even catastrophic failures.

2)Transformer Short circuits

Transformer short circuit is generally caused by the transformer winding between the windings. When the transformer is subjected to a sudden short circuit, Transformer at high and low voltage sides will be subjected to a large short-circuit current. The electrodynamic force generated by these currents will act on the transformer’s windings, leading to deformation and axial displacement of the windings.

In addition, there are some reasons lead to ternals short circuit such as defects in the internal insulation of the transformer, long-term overloading, insulation aging, transformer oil deterioration, etc

Short circuits can cause excessive current flow, overheating, and insulation damage.

3)Transformer Open circuits

Transformer open circuit is the disconnection between the input and output of the transformer, resulting in the current can not flow, which leads to the phenomenon of zero output voltage. Transformer open circuit will affect the normal operation of the circuit, resulting in equipment damage, abnormal increase in current and other problems

4)Transformer Winding faults

Shorted turns or open windings, can occur due to insulation degradation, mechanical stress, or manufacturing defects. These faults affect the electrical continuity of the winding, leading to current imbalances, overheating, and decreased efficiency.

Thermal Faults

Thermal faults in transformers primarily result from excessive temperatures, inadequate cooling, or improper loading. Overloading the transformer beyond its rated capacity can cause overheating, leading to insulation degradation, increased losses, and reduced lifespan. Inadequate cooling mechanisms, such as insufficient oil circulation or malfunctioning cooling fans, can also contribute to thermal faults. High ambient temperatures, poor ventilation, and operating in harsh environments exacerbate the risk of thermal issues.

Symptoms of thermal faults include excessive temperature rise, increased noise levels, and abnormal odor. Thermal faults can lead to insulation failure, decreased efficiency, and accelerated aging of transformer components.

Detecting and diagnosing these faults promptly is crucial to prevent further damage and ensure the reliability of the transformer.

What is Transformer Test Bench ?

Transformer test bench is a comprehensive equipment designed to simulate a wide range of electrical and environmental conditions which is used for ex-work and electrical maintenance inspection on various transformers. They allow comprehensive testing and evaluation of transformers, facilitating fault detection and diagnosis.

It’s widely applied in the fields of power supply and distribution, power transformer manufacturer, transformer maintenance center, industry and mining enterprises.

These transformer test system are equipped with various instruments, control systems, and software to replicate real-world operating conditions and assess the transformer’s performance, efficiency, and reliability.

The important components commonly found in transformer test benches

Transformer Control System: Enables precise control and monitoring of test parameters, test sequences, and safety interlocks. It may include a software interface for automated testing and data acquisition.

Power Supply: Provides the required electrical power to simulate the transformer’s primary and secondary winding voltages and currents.

Measurement Instruments: Includes various meters, sensors, and instruments for measuring parameters such as voltage, current, power, impedance, and frequency during testing.

Voltage regulating system : Used to apply specific loads to the transformer to evaluate its performance under different load conditions and measure parameters like efficiency, voltage regulation, and temperature rise.

Protection and Safety Systems: Ensure the safety of the testing environment and equipment by incorporating features like overcurrent protection, overvoltage protection, short-circuit protection, and grounding systems.

Cooling System: Some transformer test benches are equipped with cooling systems to simulate or control the temperature conditions experienced by the transformer during operation.

Test Software and Data Management: Enables the configuration of test parameters, real-time monitoring of test results, and data storage for analysis and reporting purposes.

Comprehensive Testing Capabilities of transformer test system

The main advantages of transformer test bench is the ability to perform comprehensive testing for various transformers. The transformer test bench can simulate various critical parameters such as voltage variations, winding resistance, temperature extremes, and insulation resistance measurements.

By subjecting transformers to these simulated conditions, it is possible to accurately detect and diagnose faults.

Transformer test benches are capable of conducting a wide range of tests to evaluate transformer performance, including:

Routine tests:

Transformer power frequency withstand voltage testing

Transformer inductive withstand voltage testing

Transformer insulation resistance testing

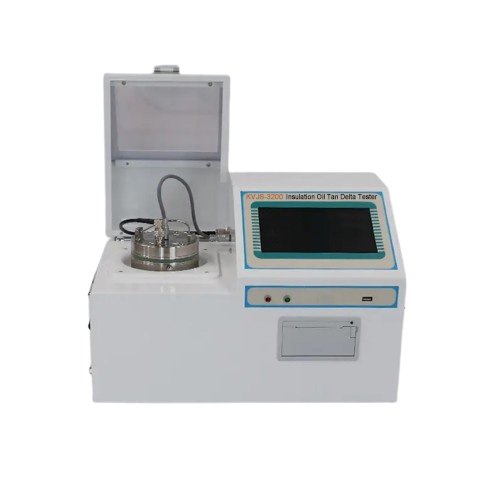

Transformer oil testing (transformer oil breakdown, acidity, dewpoint, flashpoint, capacitance & tan delta, dissolved gas analysis)

Transformer winding resistance testing

Transformer turns ratio testing

Transformer load/no-load current & loss testing

Transformer capacitance & tan delta testing

Transformer short circuit impedance & load loss testing

Impulse voltage testing

Insulation Testing and Diagnostics

Insulation breakdown is a common fault in transformers, which can lead to reduced efficiency and even catastrophic failures.

Transformer test bench products play a vital role in identifying insulation faults through various diagnostic tests. One such test is the insulation resistance test, which measures the resistance between the windings and the transformer’s core.

By assessing the insulation condition, potential faults like insulation degradation or moisture ingress can be detected, allowing for timely repairs or replacements.

Winding and Core Fault Detection

Faults in transformer windings and cores can significantly impact its performance and longevity. Transformer test bench products offer specialized tests to diagnose these faults accurately. For instance, winding resistance tests can identify high resistance or shorted turns, enabling targeted repairs. Additionally, core tests such as core loss measurements and magnetizing current tests help detect core-related faults like laminations or magnetic imbalances.

Diagnosis of Load and Overheating Issues

Transformers can experience load-related issues, such as overheating, which can lead to reduced efficiency and potential failures.

Transformer test bench products enable load testing under controlled conditions. By subjecting the transformer to different load scenarios, these test benches can identify load-related faults, including thermal anomalies and excessive losses.

This allows for corrective measures to be taken, such as optimizing cooling systems or adjusting load distribution.

Detection of Short Circuits and Open Circuits

Short circuits and open circuits are critical faults that can severely impact transformer operation. Transformer test bench products provide specialized tests to detect these faults accurately.

Short circuit tests involve applying high currents to the transformer to measure impedance and evaluate the ability to withstand short circuit conditions.

Open circuit tests, on the other hand, help identify open circuits or faulty connections within the transformer windings. By conducting these tests with transformer test bench products, faults like short circuits and open circuits can be precisely diagnosed, allowing for necessary repairs or replacements.

Transformer Test Beaches Features

Transformer test benches are the comprehensive systems which is applied for testing and evaluating transformers. Here are some key features and benefits of transformer test benches as belows:

Professional application : Applied for different voltage level transformer, HV switches . It is applicable for transformer factory, power company , research institution.

Multiple Test Functions: They include some tests such as turns ratio test, winding resistance test,insulation resistance test, no-load loss test, withstand voltage test, partial discharge test etc. It can provide a versatile work beach for conducting multiple tests in a single setup.

Precise Measurement and Control: Adopted incorporate advanced control system and accurate measurement instruments to ensure precise measurement of electrical parameters such as voltage, current, power, impedance, and frequency. That enhances the accuracy and reliability of the test results.

User-Friendly Interface: Graphical displays and intuitive control panels. This simplifies the operation and configuration of test parameters

Safety Features: Built-in safety features to protect the operator and equipment during testing. These include features such as overcurrent,overvoltage, short-circuit protection, and grounding systems. Safety interlocks ensure that tests are conducted in a secure manner.

Data Management and Reporting: Test benches often have data management systems that enable the storage, analysis, and reporting of test results.

Flexibility and Customzied : Test benches are customized and designed to apply to different transformer test request to meet specific test needs.

Standard Compliance: Test benches are designed to meet relevant industry standards and regulationsGB1094, IEC60076 or ANSI C57 for transformer testing

How to choose transformer test bench manufacturer? — Buyers guides

Professional transformer test bench manufacturer can be hard to find, especially if you’re looking for customized features to meet your transformer test request. Here are some of the things you should consider when choosing the right transformer test bench.

Testing Capability

Transformer test bench should be capable of performing the necessary tests for the transformers factory according to transformer different voltage level.

That is included some transformer common tests such as turns ratio, winding resistance, insulation resistance, no-load loss, withstand voltage, and partial discharge.

Accuracy and Reliability

Transformer comprehensive test system offer the test data results for judging the transformer performance . Accurate and reliable test results are crucial for ensuring the quality of transformers.

Training and Technical Soutien

You may face difficulties in effectively operating the test bench and interpret the test results. Obtaining the reliable technical support for troubleshooting and resolving issues is essential for smooth operation from transformer test bench manufacturer.

Calibration and Maintenance

Test benches require regular calibration and maintenance to ensure accurate and reliable testing. Managing the calibration schedule and finding qualified manufacturer for maintenance can be a concern for you.

Transformer Test Bench Cost:

Transformer test benches can be a significant investment for factories, and cost is often a primary concern. Balancing the budget with the required testing capabilities and quality can be a challenge.

Choose a manufacturer that offers high-quality transformer test equipment at a competitive rate

FAQs

Q1: Can transformer test bench products detect all types of faults?

A1: Transformer test bench products are designed to detect a wide range of faults, including electrical, thermal, and mechanical issues. However, the effectiveness of fault detection may vary depending on the specific test bench and diagnostic techniques used. It is essential to choose a test bench that aligns with your specific requirements and covers the types of faults you wish to diagnose.

Q2: How often should transformer testing with a test bench be conducted?

A2: The frequency of transformer testing depends on various factors, such as the transformer’s age, load conditions, and operating environment. Generally, routine testing is recommended at regular intervals to monitor the transformer’s health and detect potential faults early on. Additionally, transformer testing with a test bench should be performed during commissioning, after major repairs or modifications, and as part of preventive maintenance programs.

Q3: Are transformer test bench products suitable for both new and aged transformers?

A3: Yes, transformer test bench products are suitable for both new and aged transformers. For new transformers, testing with a test bench helps verify their performance and quality before deployment. In the case of aged transformers, test bench products are instrumental in assessing their condition, detecting faults, and determining the need for maintenance or refurbishment.

Q4: Can transformer test bench products replace field testing and maintenance?

A4: Transformer test bench products complement field testing and maintenance activities but do not replace them entirely. While test bench products provide comprehensive testing capabilities in a controlled environment, field testing and maintenance are essential for assessing the transformer’s performance under real-world conditions and addressing site-specific issues. A combination of both approaches ensures a thorough evaluation and maintenance strategy for transformers.

Conclusion

By providing comprehensive testing capabilities, advanced diagnostic techniques, and optimized maintenance strategies, transformer test bench products have become indispensable tools in the power industry.

Whether it’s diagnosing faults in new or aged transformers, ensuring compliance with industry standards, or optimizing maintenance activities, these products play a vital role in maintaining the reliability and performance of transformers. Incorporating transformer test bench products into testing and maintenance processes can significantly enhance the overall efficiency and longevity of transformers, benefiting the power industry and end-users alike.