What is tan-delta test ?

Tan-delta test is also know as dielectric losss testing. Dielectric loss refers to the energy loss that occurs in a dielectric material (such as the insulation of a transformer) when an electric field is applied to it. The dielectric loss is caused by the electrical resistance of the material, which results in the conversion of electrical energy into heat.

In an ideal dielectric material, there would be no energy loss, as all of the energy would be stored in the material’s electric field. However, real-world materials have some level of electrical resistance, which results in some of the electrical energy being converted to heat energy. The amount of energy loss is typically measured as a function of the frequency of the applied electric field and is often characterized by a parameter called the “dissipation factor” or “tan delta.”

What is principle of tan-delta test ?

The principle of the Tan-Delta test is based on the measurement of the loss angle between the voltage applied to the transformer insulation and the resulting current flowing through it. Under the action of AC voltage, the angle between the current phasor and the voltage phasor flowing in the dielectric is the power factor angle (Φ), and the complementary angle (δ) is referred to as the dielectric loss angle.

The test involves applying a voltage to the transformer insulation and measuring the resulting current. The voltage and current signals are then analyzed to determine the phase angle between them, which is known as the “Tan Delta” angle. The Tan Delta angle is a measure of the energy that is lost in the insulation material due to its resistance to electrical flow.

In general, the higher the Tan Delta angle, the lower the quality of the insulation. This is because a higher Tan Delta angle indicates that more energy is being lost in the insulation, which can lead to overheating, reduced efficiency, and other problems.

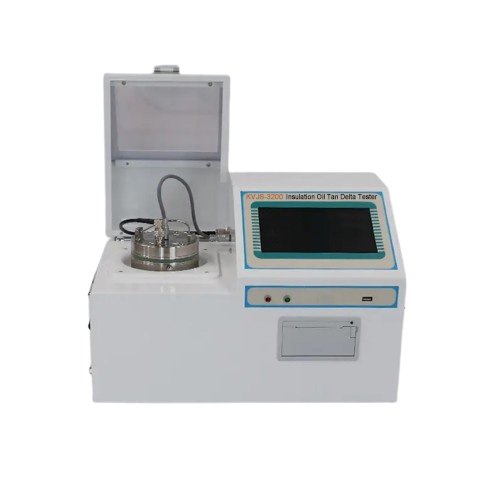

The Tan-Delta test is typically performed at a low frequency, such as 50 or 60 Hz, and the test voltage is usually less than the rated voltage of the transformer. The test can be performed using specialized test equipment, which measures the voltage and current signals and calculates the Tan Delta angle.

Why do you need to test the tan delta of transformer ?

Testing the Tan Delta (also known as Dissipation Factor) of a transformer is to help to assess the insulation quality of the transformer. The insulation in a transformer is subjected to electrical, thermal, and mechanical stresses during its operation, and over time it may deteriorate, leading to a risk of failure or breakdown.The Tan Delta test is an important tool in ensuring the reliability and safety of transformers, and it is an essential item of transformer maintenance and testing programs.

The Tan Delta test will measure the quality of the insulation material and detects any weaknesses or defects in it. It assesses the ability of the insulation to withstand the electrical stress imposed on it during operation. The test measures the loss of energy in the insulation and identifies any potential issues that could lead to failure.

By testing the Tan Delta value of a transformer, it is possible to identify any potential issues early. A high Tan Delta value indicates poor insulation quality, which can lead to problems such as arcing, overheating, and breakdown of the transformer . It can will leads to below negative impacts.

- Reduced efficiency: The dielectric loss is a measure of the energy that is lost due to the resistance of the insulation material. If the Tan Delta value is high, it means that the insulation is less effective in preventing energy losses. This can result in reduced efficiency of the transformer.

- Overheating: Dielectric loss generates heat in the insulation, which can cause the transformer to overheat. If the Tan Delta value is high, the insulation will generate more heat, which can lead to thermal degradation and reduce the lifespan of the transformer.

- Reduced lifespan: Over time, high dielectric losses can lead to accelerated degradation of the insulation, which can reduce the lifespan of the transformer.

- Safety risks: A high Tan Delta value can indicate that the insulation is weakening and may be at risk of failing, which can cause safety risks such as electrical shorts, fires, or explosions.

Transformer capacitance and tan-delta tester is important to identify and address any issues as soon as possible to prevent further damage to the transformer and ensure safe and reliable operation. When you measure the tan-delta of transformen by Transformer capacitance and tan-delta tester, the capacitance can also be obtained . The obvious change in capacitance reflects the short circuit or open circuit of one or several of the multiple capacitors. Regular testing and maintenance of transformers can help detect and address high dielectric losses before they cause major problems.