Are you worried about unexpected breakdowns in your wind or solar farm? Imagine the stress and costs of sudden power outages. VLF testing can help avoid these issues. VLF (Very Low Frequency) testing ensures the reliability of wind and solar farms by detecting insulation weaknesses in cables and electrical components. This early detection prevents failures, reduces downtime, and optimizes maintenance, ensuring a stable energy supply. If you want to make your wind and solar farms more reliable, then keep reading to learn more about VLF testing.

What Specific Components in a Wind Turbine Benefit from VLF Testing?

Wind turbines face tough conditions, and problems can cause big trouble. Ignoring these potential issues is like waiting for a storm to hit your house – it’s better to prepare. VLF testing is useful for testing wind turbine generators, transformers, and especially the long underground cables connecting the turbine to the grid. These cables are prone to insulation stress due to mechanical stress and environmental factors, which VLF testing can identify early. Dive Deeper Paragraph: Wind turbines have many parts that need to work well for the whole system to be reliable. VLF testing focuses on the parts most likely to cause problems. Here’s a breakdown:

| Component | Why VLF Testing is Important |

| Generator | Checks the stator and rotor windings for insulation weaknesses, preventing short circuits and ensuring consistent power output. |

| Transformer | Assesses the condition of the insulation within the transformer, which is crucial for stepping up voltage for grid transmission. |

| Underground Cables | Detects damage to the cable insulation caused by mechanical stress, moisture, or electrical stress, preventing costly outages. |

I remember one time when a wind farm in Inner Mongolia was facing frequent shutdowns due to cable faults. After implementing regular VLF testing, they were able to identify and replace aging cables before they failed, significantly reducing downtime. It’s all about finding the weak spots before they become major problems.

How Often Should VLF Testing Be Performed on Solar Farm Cables to Maintain Optimal Performance?

Thinking about when to test your solar farm cables? Delaying testing can lead to unexpected failures, just like skipping regular check-ups for your car can lead to bigger problems later. VLF testing should be performed on solar farm cables every 3-5 years. More frequent testing might be needed in areas with harsh environmental conditions or for older installations to prevent unexpected failures. ! Dive Deeper Paragraph: Regular VLF testing is key for keeping your solar farms running smoothly. Here’s how to plan your testing schedule:

| Factor | Impact on Testing Frequency |

| Age of Installation | Older installations (10+ years) may require more frequent testing (every 2-3 years) due to increased wear and tear. |

| Environmental Conditions | Sites with high temperatures, humidity, or soil corrosivity should test more often (every 2-3 years) to catch early degradation. |

| Load Conditions | Systems operating near their maximum capacity should be tested more frequently (every 2-3 years) due to increased stress on cables. |

For example, a large solar farm in Xinjiang faced numerous cable failures due to extreme temperature variations. After implementing a VLF testing schedule every two years, they saw a 40% reduction in cable-related downtime.

What Are the Typical Failure Modes Detected by VLF Testing in Renewable Energy Installations?

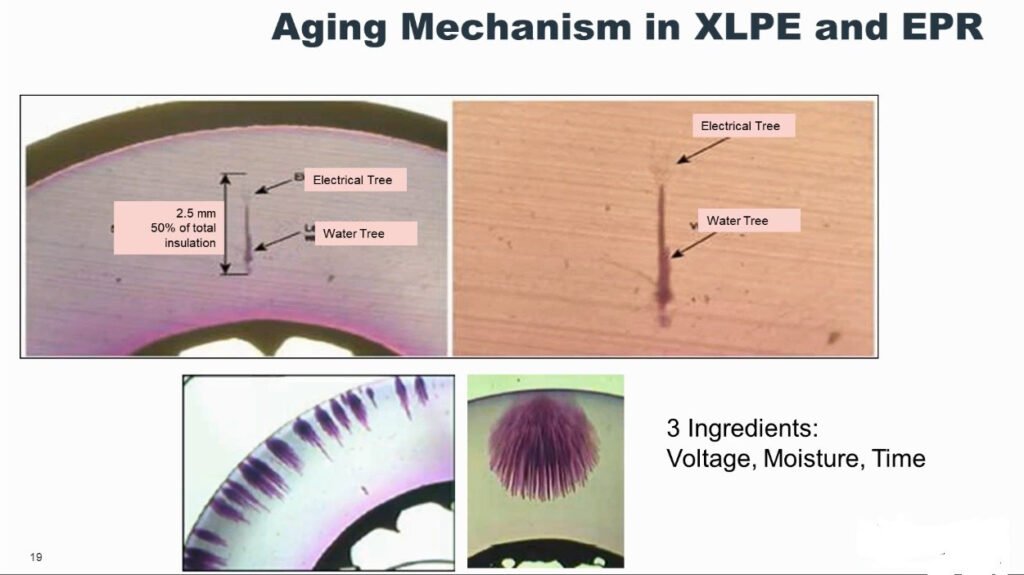

Are you aware of what VLF testing can find in your renewable energy systems? Ignoring potential failures is like driving a car without knowing if the brakes work. VLF testing commonly detects insulation degradation, water treeing, and partial discharges in cables and electrical equipment. These issues can lead to breakdowns if they are not identified and addressed early.

VLF testing is really effective because it finds different types of problems that can cause renewable energy systems to fail. Here’s a closer look:

| Failure Mode | Description | Impact |

| Insulation Degradation | Breakdown of the insulating material due to electrical stress and aging. | Leads to reduced insulation strength, increasing the risk of flashovers and short circuits. |

| Water Treeing | Formation of small, tree-like structures within the insulation due to moisture and electrical fields. | Gradually weakens the insulation, eventually causing failure, especially in underground cables. |

| Partial Discharges | Localized electrical discharges that occur within insulation voids or on the surface of insulation. | Indicates insulation defects and accelerates degradation, leading to premature failure if not addressed. |

In my experience, a solar farm in Jiangsu experienced frequent power interruptions. VLF testing revealed widespread water treeing in their underground cables, which was caused by poor cable installation. Replacing these cables based on the VLF test results prevented further unexpected outages.

Can VLF Testing Be Used to Assess the Remaining Life of Cables in Aging Solar Plants?

Do you wonder if VLF testing can help extend the life of your aging solar plants? Not using available tools is like ignoring the expiration date on your food. Yes, VLF testing can assess the condition of cable insulation in older solar plants, providing data that helps predict the remaining lifespan and plan for timely replacements.

VLF testing is a key way to figure out how much longer your old solar plant cables will last. It gives you the info you need to plan ahead. Here’s how it works:

| Assessment Aspect | VLF Testing Contribution | Benefit |

| Insulation Condition | Measures the dielectric strength and identifies any existing insulation defects. | Provides a clear indication of the cable’s current health and its ability to withstand operational stresses. |

| Trend Analysis | Compares VLF test results over time to monitor the rate of degradation. | Enables accurate prediction of when cables will need to be replaced, optimizing maintenance schedules and budgets. |

| Risk Management | Helps prioritize cable replacements based on the severity of detected defects and the potential impact of failure. | Reduces the risk of unexpected outages and extends the operational life of the solar plant. |

|

I know of a solar plant in Gansu that used VLF testing to assess their 15-year-old cables. The results showed that some cables were still in good condition, while others needed replacement. By focusing on the most critical cables, they saved money and avoided a complete system overhaul.

Conclusion

VLF testing is essential for ensuring the reliability and longevity of wind and solar farms. It helps detect potential issues early, prevent downtime, and optimize maintenance schedules, securing a stable and efficient energy supply.