Batteries are an essential element of any electrical system, yet they frequently go unnoticed during routine maintenance. It is critical need for proper battery care.

Due to the complexity of electrochemical reactions in batteries, combined with varying materials, structures, manufacturing processes, and environmental conditions, the characteristics of batteries from different manufacturers can differ significantly.

Even batteries produced by the same manufacturer can exhibit a degree of variability. To date, there is no simple and effective method available globally that can quickly and accurately assess battery performance. Testing battery performance and predicting failures remains a complex challenge in electrochemical measurement.

The status of stationary acid-proof and explosion-proof lead-acid batteries, widely used in industries such as electric power, communication, finance, and transportation, can be evaluated by measuring terminal voltage and checking electrolyte density, liquid level, and temperature. However, the sealed design of valve-regulated lead-acid (VRLA) batteries complicates the assessment of their health status.

Consequently, traditional testing and maintenance methods for acid-proof and explosion-proof batteries are no longer applicable to VRLA batteries, presenting a significant challenge in current battery management.

Battery charger discharger is a very effective way to proceed the battery maintenance .

1. What is battery charger discharger

1.1 Overview of Battery Charger Discharger

A battery charger discharger is an advanced piece of equipment designed to perform two critical tasks: charging a battery to its full capacity and discharging it to measure performance, capacity, and other key parameters. These systems are commonly used for testing and maintaining batteries in various applications, ensuring their optimal operation and longevity.

1.2 Significance of Battery Maintenance and Testing

Role in Prolonging Battery Life

Proper maintenance and regular testing with a charger discharger system help:

- Prevent premature battery failures by identifying issues like sulfation or capacity loss early.

- Extend battery lifespan by optimizing charge/discharge cycles and reducing stress on battery components.

- Ensure that the battery operates at peak efficiency for its designed lifetime.

Ensuring Safety and Reliability in Power Supply Systems

Batteries are integral to critical systems, such as uninterruptible power supplies (UPS) in hospitals, grid storage systems for renewable energy, and electric vehicles. Proper testing ensures:

- Safe operation by detecting and mitigating risks like overheating or short circuits.

- Reliable performance in emergencies, preventing system downtimes or data losses.

- Compliance with industry safety standards and regulations, fostering trust in the equipment’s performance.

2.The principle of battery charger discharger

Currently, the standard testing method involves routinely measuring battery terminal voltage and conducting annual discharge capacity tests. We propose the following insights:

Terminal Voltage and Capacity: The terminal voltage of a battery under floating charge does not accurately correspond to its capacity. Poor-performing batteries can still show acceptable voltage under floating charge conditions, meaning that terminal voltage cannot reliably reflect battery performance.

Full Capacity Discharge Testing: A full capacity discharge test remains the most accurate and effective method for determining the actual capacity of a battery group. The capacity of a battery group is determined by the weakest battery within it. Thus, testing can focus on the delayed battery, measuring its capacity to infer the entire group’s performance. By discharging the battery group at a specified constant current and monitoring the voltage of each battery, we can identify the actual capacity released when any battery reaches its cut-off voltage. This method yields true and accurate results.

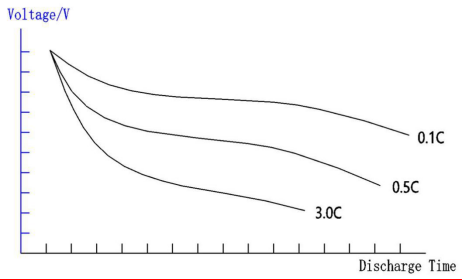

The discharge curve of a battery reveals that:

Discharge Curve Consistency: The same discharge curve indicates similar battery performance. Batteries of the same specifications from the same manufacturer, using the same formulation and production process, will have consistent characteristic curves, disregarding minor production variances.

Discharge Rates Among Cells: Cells within the same group may discharge at different rates due to variations in their capacities. When discharging, each cell may have a different capacity but experiences the same discharge current, leading to differing discharge rates and corresponding curves.

2.2 Constant Current Principle

The tester’s discharge circuit employs PWM and PID closed-loop control technology managed by an ARM (central processing unit). This setup allows the power circuit to operate accurately at the designated discharge current. For instance, during constant current discharge, when the battery voltage begins to drop, the ARM controller detects the decreased current through a feedback sensor and adjusts the controlled power loop accordingly. This adjustment process is repeated, achieving real-time regulation. The same principle applies to constant power, with voltage values also needing consideration alongside current values.

2.3 Charging Principle

Floating Charge and Equalized Charge: Both are modes of battery charging.

1.Floating Charge Principle: When the battery is fully charged, the charger continues to supply a constant floating charge voltage and minimal current. This setup allows the battery to naturally release energy once the charger stops, which is why small UPS systems often utilize floating charge to manage natural discharge.

2.Equalized Charge Principle: Charging the battery with a fixed current for a set duration results in faster charging. This method is commonly used by professional maintainers to preserve battery health and activate its chemical properties.

3.The intelligent charging instrument produced by our company automatically switches between floating and equalized charging modes based on the battery’s working state, maximizing the benefits of both methods for quick charging and prolonged battery life.

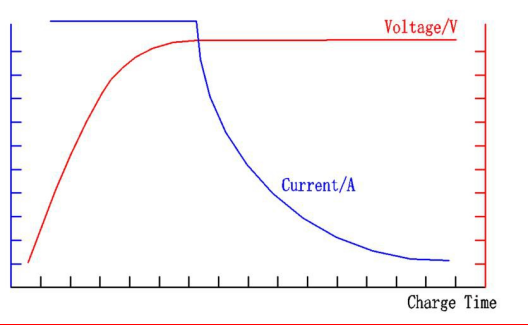

The following illustrates the curve of battery voltage and current variations during charging:

3. Key Applications of Battery Charger Discharger

3.1 Power Backup Systems

Battery charger dischargers play a crucial role in maintaining the reliability of backup power systems, particularly in critical scenarios.

- Usage in UPS (Uninterruptible Power Supply) for Emergency Power:Battery systems in UPS setups rely on charger dischargers to ensure they are ready for immediate operation during power outages. Regular testing helps verify the battery’s ability to deliver power when needed.

- Maintaining Critical Operations:**In environments like hospitals, data centers, and telecommunications networks, the continuous availability of power is non-negotiable. Battery charger dischargers help maintain and optimize these systems, ensuring smooth operation even under adverse conditions.

3.2 Renewable Energy Storage

With the increasing adoption of renewable energy, effective energy storage solutions are critical.

- Testing and Optimizing Solar and Wind Energy Storage Systems:Charger dischargers ensure that batteries in renewable setups can store and release energy efficiently, supporting sustainable power supply.

- Role in Managing Charge/Discharge Cycles for Sustainable Energy Use:**Batteries must endure frequent charge/discharge cycles in renewable systems. Regular testing enhances performance, reduces degradation, and ensures consistent output over time.

3.3 Electric Vehicle (EV) Batteries

As EV adoption accelerates, battery charger dischargers are essential for testing and maintenance.

- Application in Testing and Calibrating EV Battery Packs:Charger dischargers evaluate the performance of EV batteries, ensuring they meet required capacity, efficiency, and safety standards.

- Supporting R&D for New EV Battery Technologies:**In research and development, charger dischargers help test prototypes, refine battery designs, and improve energy density and cycle life.

3.4 Industrial Equipment and Systems

Industrial applications rely heavily on batteries for operational efficiency and uptime.

- Ensuring Reliability in Forklifts, Automated Systems, and Robotics:Charger dischargers ensure these systems operate without interruptions, maximizing productivity and safety in industrial environments.

- Regular Maintenance for Long-Term Efficiency:**Routine charge/discharge testing prevents unexpected battery failures, reducing downtime and repair costs.

3.5 Military and Aerospace Applications

Batteries in military and aerospace systems must meet the highest reliability standards.

- Ensuring High Reliability for Mission-Critical Operations:Battery charger dischargers test batteries used in mission-critical devices, ensuring they perform flawlessly under demanding conditions.

- Testing Batteries Under Extreme Conditions:**Military and aerospace applications often involve extreme temperatures, vibrations, and pressures. Charger dischargers verify battery performance and durability in such challenging environments.

3.6 Grid Energy Storage

Large-scale energy storage systems depend on charger dischargers for optimal operation.

- Role in Managing Load Balancing and Energy Distribution:Charger dischargers test the readiness of grid-connected batteries to handle peak loads and distribute energy efficiently across the network.

- Importance in Large-Scale Battery Banks for Stabilizing the Grid:**As renewable energy sources fluctuate, charger dischargers help ensure that large-scale battery banks provide stability and resilience to power grids.

By addressing these diverse applications, battery charger dischargers significantly enhance the performance, reliability, and lifespan of battery systems across industries.

4. Benefits of Using Battery Charger Discharger

4.1 Improved Battery Performance

One of the primary advantages of using battery charger discharger systems is the enhancement of overall battery performance.

- Balancing Cells to Enhance Capacity and Runtime:In multi-cell battery systems, uneven charge levels between cells can lead to reduced efficiency and performance. Charger dischargers perform cell balancing, ensuring all cells operate at optimal levels, which:

- Maximizes battery capacity.

- Extends runtime during operations.

- Reduces the likelihood of cell failures caused by overcharging or undercharging.

4.2 Predictive Maintenance

Battery charger dischargers enable proactive management of battery systems by facilitating predictive maintenance.

- Identifying Early Signs of Degradation to Prevent Failures:By regularly monitoring and testing batteries, charger dischargers detect:

- Capacity loss, which may indicate aging or damage.

- Abnormal voltage, temperature, or current patterns, which could signal internal defects.Early detection allows users to address issues before they escalate, thereby:

- Reducing the risk of unexpected battery failures.

- Enhancing safety in critical applications.

- Improving operational reliability.

4.3 Cost Efficiency

Cost savings are another significant benefit of incorporating battery charger discharger systems into maintenance protocols.

- Reducing Costs by Prolonging Battery Life and Reducing Downtime:Regular charge/discharge testing and maintenance can:

- Extend the functional lifespan of batteries, reducing the frequency of replacements.

- Minimize downtime caused by battery-related failures, which can be costly in critical applications like data centers or industrial operations.

- Lower the total cost of ownership (TCO) for battery systems by preventing unnecessary repairs or replacements.